Calculator

Calculate the costs and savings of implementing Vacuum Insulated Piping (VIP) in your project.

Fill out this simple form and receive a complete report with instant results.

Capex in Euros – vacuum insulation

Empty

Payback

Empty

If you invest in our technology, your payback in years will be: Empty

The above are guidelines. To find out the real value of your

project, do not hesitate to contact us.

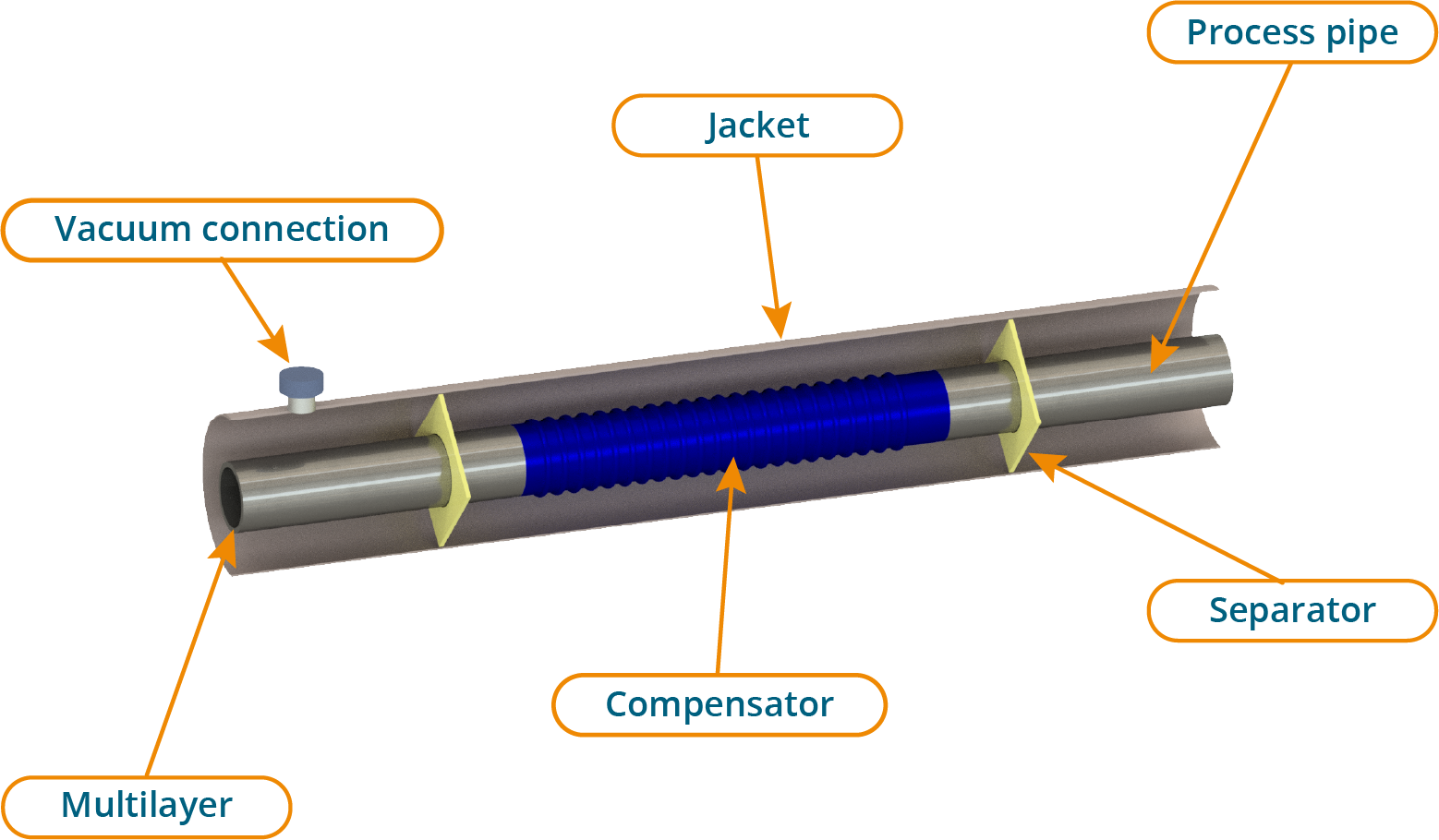

Our pipes

Traditionally polyurethane foam insulation has been used as a method of insulation due to its apparent low cost of implementation. However, its efficiency declines during the first years of implementation. This leads to increasing evaporation rates,

mainly due to:

- Degradation of the material under extreme indoor/outdoor temperature changes.

- Degradation due to the effects of thermal expansion and compression of the pipe.

- Exposure of the process piping due to moisture condensation in cracks or joint defects due to changes in the direction of pipe travel and/or flow diversions. (This will also lead to the formation of ice on the surface).

You may not notice the variations in evaporation rate on a day-to-day basis, but as the years go by and when compared to the initial properties of the system, the process fluid consumption required to maintain the same level of production will get higher and higher.

Advantages of vacuum-jacketed piping

- Significant reduction in thermal losses caused by heat leakage.

- Rapid return on investment in the installation of new vacuum-jacketed piping.

- Long service life:

- Virtually no decrease in thermal performance of vacuum jacketed pipe for 10 - 15 years.

- Stainless steel construction allows for intensive use depending on the design time.

- Low maintenance cost, limited to visual integrity inspection based on plant inspection program or monitoring of pressure or temperature gauges in piping systems with monitoring elements. Vacuum check and O-ring replacement are both recommended after 10 - 15 years of service.

- The significant reduction in weight and volume versus a polyurethane foam jacket alternative means savings on transportation costs, reductions in design space and simplified field installation.

- Vacuum piping also acts has significant safety advantages. The outer jacket of the vacuum pipe serves as a containment system in case of leakage to the outside of the process pipe.

- In case a segment needs to be replaced, the modular design allows for quick replacement, since the detection of the failure is immediate, as well as the replacement with another prefabricated segment.

What Cryospain offers

On-site measurements.

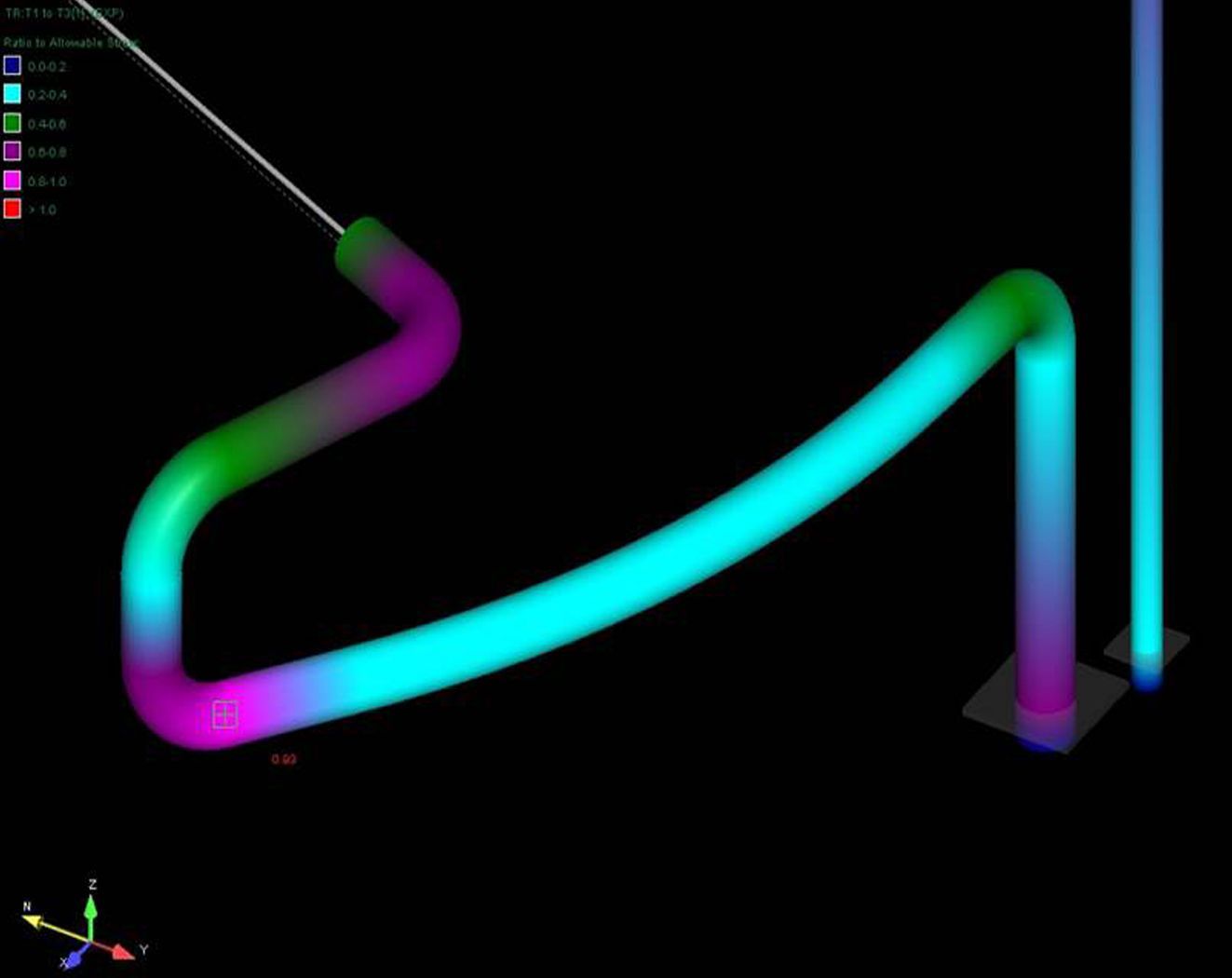

Thermal analysis of your installation, design review and optimization based on thermal loads, external loads, fatigue, surge analysis, flexibility and if necessary design and recommendation of pipe supports.

Detailed proposals describing each element of your system.

Maintenance and spare parts.

Installation of equipment or supervision of execution works by Cryospain's on-site engineer.

© 2023 CRYOSPAIN